A strategic collaboration combining cutting-edge automation with packaging expertise

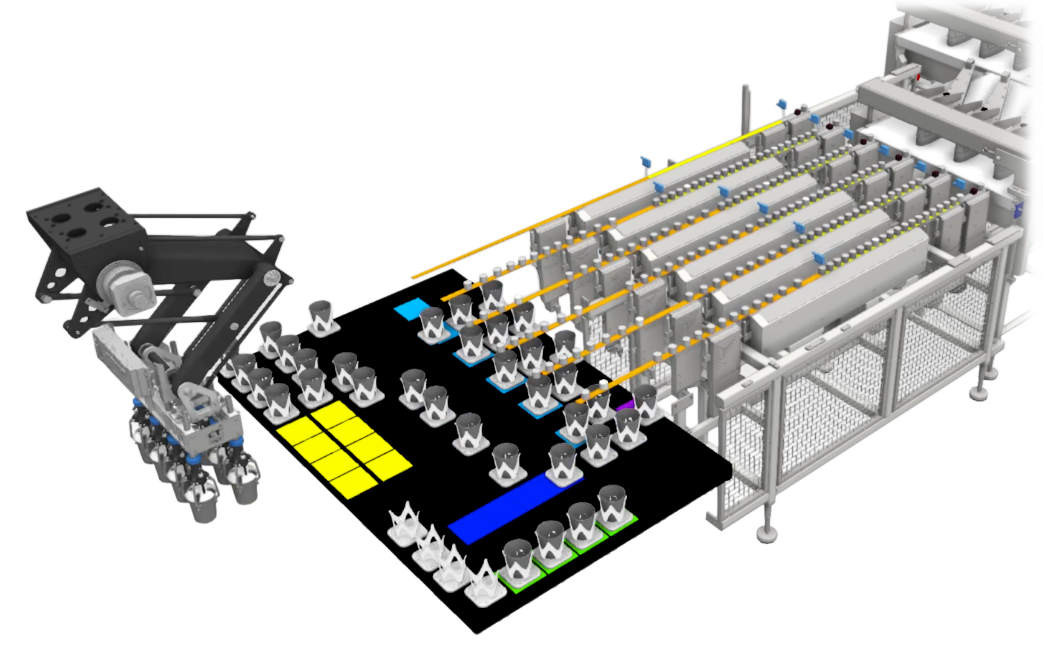

CT Pack and B&R Industrial Automation join forces with the development of the MCS – Magnetic Carrier System, an innovative solution that takes food packaging to new levels of efficiency, precision, and hygiene.

This collaboration combines CT Pack’s long-standing expertise in food and non-food packaging with B&R’s ACOPOS 6D magnetic levitation technology, a leader in industrial automation solutions. The result is a machine capable of handling transport, counting, and automatic filling of small products with continuous flow and millimeter-level precision.

Benefits of the collaboration

- Integrated innovation: magnetic levitation allows contactless movement, increasing reliability and reducing maintenance.

- Total flexibility: easily handles different flavors, formats, and recipes without production stops.

- Operational efficiency: tool-less format changes and centralized control through an intuitive HMI interface.

- Modularity and scalability: easily expand lines and capacity without halting production.

- High hygiene standards: FDA-compliant product contact parts and a fully washdown-capable structure.

Thanks to this synergy, CT Pack transforms B&R’s advanced technology into measurable, real-world performance, ensuring continuous, precise, and high-quality operation even in the most demanding production environments.

MCS is not just a machine: it is the result of a technological collaboration that redefines the future of packaging.