High speed integrated box loading system. This modular machine forms box/tray from a flat blank, fills and seals boxes.

It integrates a box former, a collating unit with robot and a box sealer or a lid applicator. Fully suitable for a compact secondary

packaging solution; this machine can be provided with different features like double collating system or high-speed feeding.

The system can also well be integrated for multipack wrapper feeding.

Suitable for multipacks and display boxes.

Available Options:

- Hood applicator, up to 20 hood per min

- Double collating system to receive the products from two flows

- Stainless steel construction

- Lid applicator instead of standard box closing unit

- Special applications for speeds above 600 product per min

Hygienic and Design Requirements:

- Frame in painted steel or stainless steel according to user’s needs

- Enhanced accessibility to the various parts of the machine

- All parts in contact with the product are FDA approved

Main Features:

- Product input up to 600 products per minute with 1 or more infeeds

- Max. 40 boxes per min single head, 80 boxes per min double head

- With 2 axis or 3 axis robot

- With vacuum picking and flexible head

- Different type of box closing system

- Safety guards with interlocked sensors

- Electrical cabinet (with PLC, servodrives…)

- Painted steel structure

- Lexan safety doors

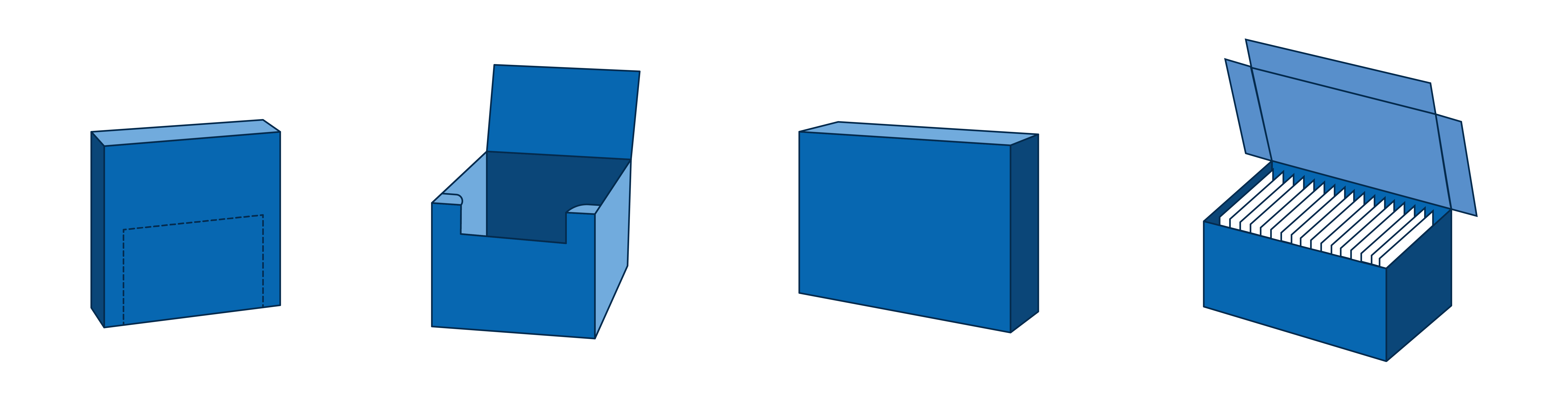

Box Type