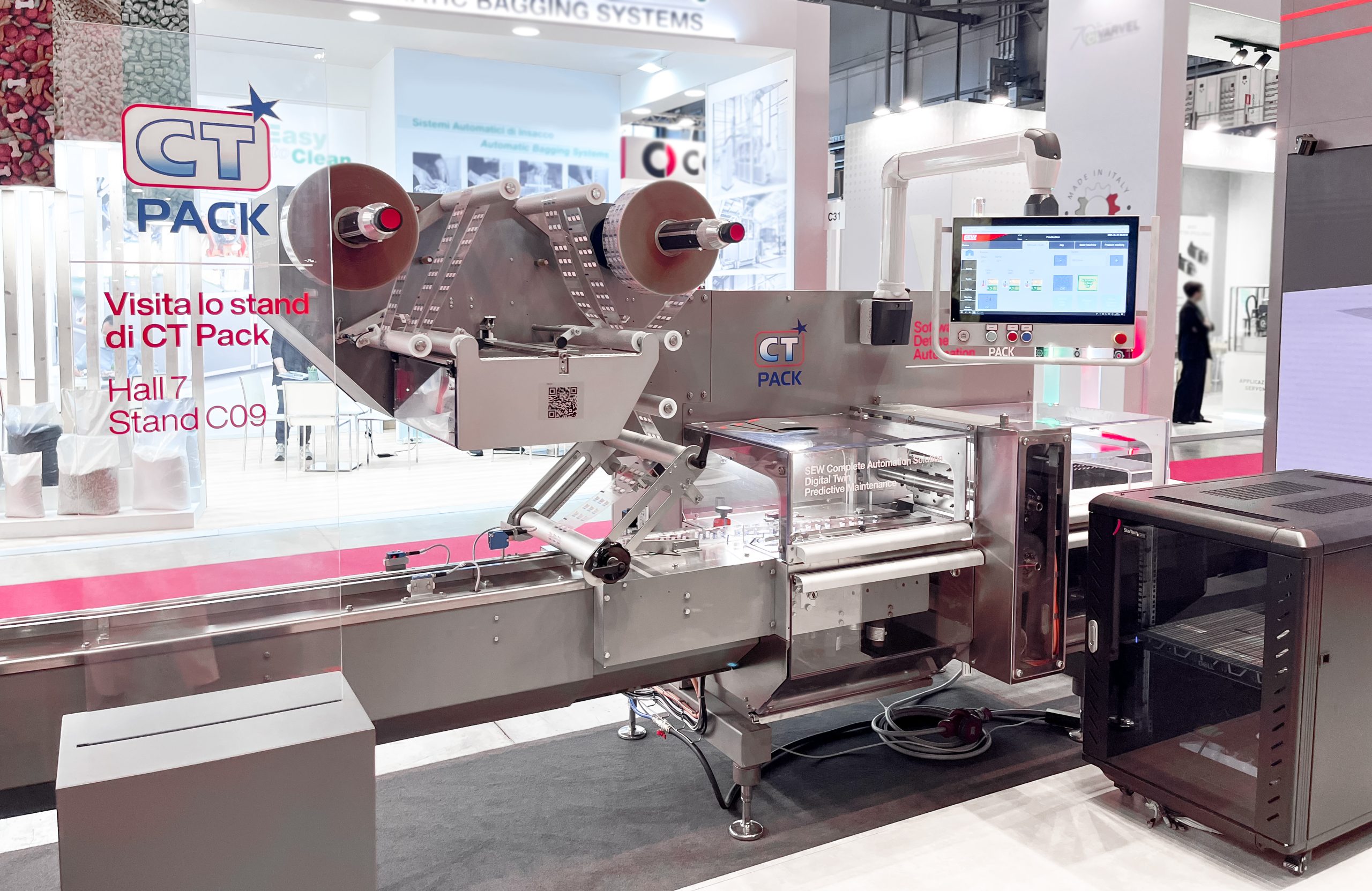

Our M01 flowpack with SEW-Eurodrive Italia automation

All the benefits of software-driven automation for our innovative, fully digital flow wrapping machine with high performance and maximum reliability.

Our M01 Flowpack represents an evolution for the packaging industry with machine automation by SEW-Eurodrive Italia, managed via Virtual PLC: IT & OT are integrated for simplified industrial automation, where software manages and controls components without relying on specific hardware configurations.

The benefits of Virtual PLC and Software Defined Automation:

- Efficient control of the production line

- Greater flexibility

- Easier access to management systems

Our M01 at IPACK-IMA 2025

“The software-defined integration developed in collaboration with SEW-EURODRIVE has allowed us to create a high-performance, fully digital flowpack that can quickly adapt to the most complex production requirements,” says Federico Tagliatti, Software & Commissioning Manager at CT Pack. “The platform is designed to guarantee maximum operational flexibility and a significant reduction in machine downtime. Thanks to an intuitive interface and scalable architecture, we offer our customers an advanced yet easy-to-use tool designed to improve ROI and accompany the food industry on the path to smart manufacturing”.

Fully equipped with SEW technology, the machine is automated in every aspect, from motion control to visualisation and safety.

“Thanks to the MOVI-C® automation platform, the system is designed to be completely open for integration, thus offering maximum flexibility and a significant increase in productivity,” says Bruno Docimo, Application Engineering Consultancy & TFS Packaging Team Leader at SEW-EURORDIVE Italia. “Every single component, from the brushless motor with DDI interface to the drives, is interconnected and communicates in real time with the rest of the ecosystem. This approach allows total control of the entire production cycle, from digital twin simulation to an advanced software orchestration system. In addition, predictive maintenance, supported by state-of-the-art sensor technology, simplifies production processes and improves operational efficiency, leading to tangible and lasting results”.

The collaboration with SEW’s partners has allowed the digital model of the machine to be placed side by side with the packaging machine: iPhysics’ Digital Twin Machinering, which enables realistic production simulations; 40 Factory MAT’s platform for monitoring machine performance in real time; and Desys’ Virtual Tour for digitising machines and plants with a visual and immersive approach.

Digital integration for packaging: SEW technology for machine automation

The entire machine automation of our M01 Flowpack was realised with SEW-EURODRIVE solutions, integrating gearmotors with MOVILINK® DDI digital motor interface; the compact and versatile MOVITRAC® advanced frequency inverter; the UHX 65 controller from the modular MOVI-C® automation platform; Digital IO and Safety.

The pre-compiled MOVIKIT® software modules for machine automation with already developed and debugged motion functions enable faster development and testing times.

Using component sensing and the MOVILINK® DDI digital motor interface, it is possible to analyse gearmotor data in real time, optimise maintenance and reduce downtimes.